The Future of Electronics Manufacturing

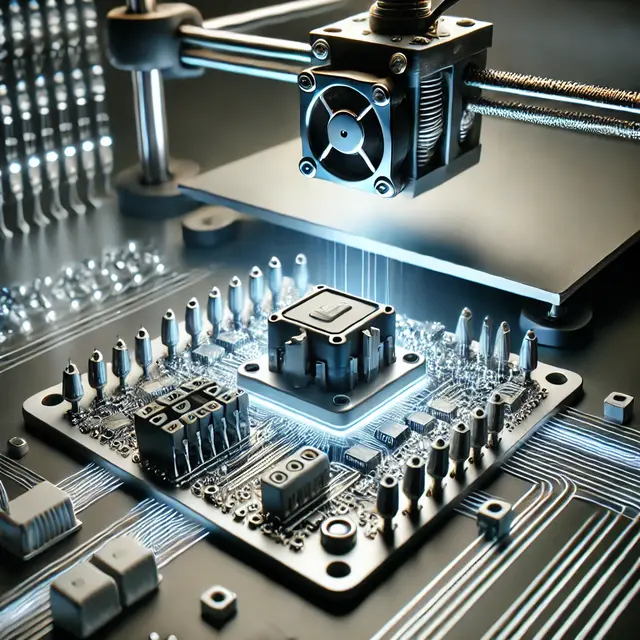

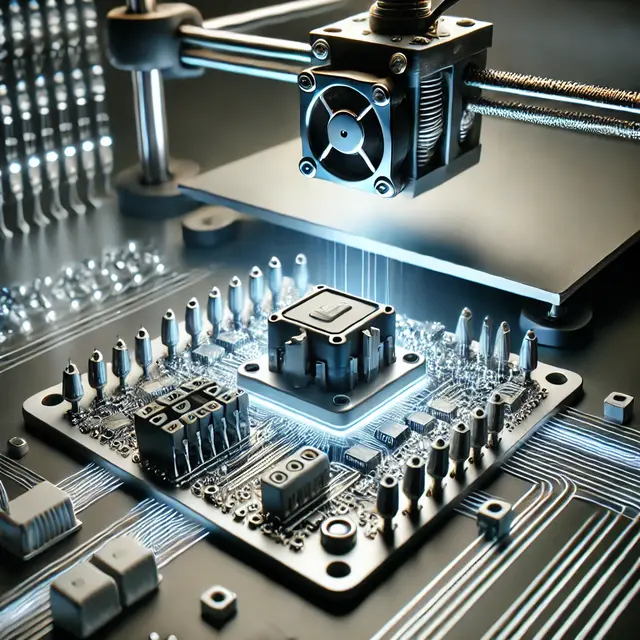

The rise of additive manufacturing has sparked a revolution in many industries, and electronics is no exception. 3D-printing in consumer electronics has changed the way products are designed, manufactured, assembled, and customized. Instead of going through the traditional kinds of multiplicative processes, now they chip off an intricate integrated circuit with its many components directly out of single printing—saving up on time and needed resources.

And with this evolution, 3D-printed electrical switches become utterly crucial to home automation, smart devices, and small-sized technology. They are expected to be so compact and knitted that their placement either inside case covers or among hidden walls is more acceptable now-as well as environmentally borrowed, etc.

What Makes 3D-Printed Electrical Switches Revolutionary?

Simply speaking, the 3D-printed electrical switch serves the same purpose as a normal physical switch would, but with one small twist: It is printed in the same operation as its corresponding components into the body of the gadget. The advent of conductive materials, inks, and filaments extends the dimensions of printed circuits toward durability and extreme customization.

Today, instead of printed and indirectly installed switching mechanisms into the housings, or control surfaces, companies no longer need to buy other switch mechanisms to install. Fewer components mean less time consumed in assembly, along with lots of design flexibility and different form factors.

For example, 3D-printed electrical switches are best for integrated walls, furniture, or control panels under home lighting systems unchecked by hardware for the most minimalist look.

Boosting Innovation in Consumer Devices

Whether 3D-printing in consumer electronics is integral to an industry or not, being mainstream implies that the speed of technology evolution is amplified. Major companies and start-ups are daring the designs they once ruled out as too complex or expensive to handle.

For instance, 3D-printed switches embedded in wearable devices are possibly curved touch surfaces that fit to the body, while most smartwatches have found IoT devices to achieve the desired thinness and weight reduction.

The possibility of emergent customizability hinges on the consumer and the modeler. It is possible to have electronics devices tailored to suit one’s personal style, hand size, or ergonomic preferences. Besides, since there is no need for molding, there is little wasted time and money involved in tweaking the knob here and there to perfect that design according to target market feedback.

How 3D-Printed Electronics Are Powering Consumer Switches

Environmental and Economic Advantages

Traditional electronics tend to produce pollution in the form of discarded raw material waste; torn out, intact-useless leftover componentry is wasted. 3D-printing in consumer electronics will reduce to a significant extent those materials wasted since only the exact amount of material needed to produce each particular component is used in a smart manner.

A corresponding perspective further allows the development of cheaper ways, benefiting promotional costs using less labor, no kits or transportation due to more streamlined processes. This is great for small businesses who would have equally felt this revolution in any other way and work toward the consumer tech market.

Highly repairable 3D-printed electrical switches are an extraordinary and future concept. If a device stops working, an individual “maybe” several layers or switch portions could be 3D-printed and then swapped out without discarding the entire product—a product-enhancing circular economy.

Real-World Applications and Future Potential

From smart homes where switches illuminate the lights, draw the blinds, or even turn on music speakers, 3D readily applies the ultra-needed electronic structures into an interior wall or furniture. Certain education kits are teaching children the basic electronics principles through printing circuits and exemplary 3D electrical switches, thus encouraging the broader inculcation of hands-on STEM learning.

Slight experimentation is ongoing in aerospace and medical scenarios, and again, in the works are lightweight control panels and embedded monitoring devices. By the time the printing inks become more reasonable and the material properties grow even finer, these are coming relatively closer to getting mass deployment.

Thus, when innovation and functionality forge ahead with credit to related technology, 3D-printing in consumer electronics is very much in the present, rather than in the future. Not to speak of 3D-printed electrical switches, which seem to make technology interaction easier, ushering in a quiet but influential transformation.

3D-printed electrical switches tech is reshaping 3D-printing in consumer electronics with more customization, less waste, and smarter design integration.

The Future of Zero-Trust Pricing and Cybersecurity Castle Models